Continuous Ice Cream Freezer / Margarine Crystallizer

- Availability: On Order

- Brand: Armfield

- Product Code: FT25

- Product viewed: 54792

Share:

Continuous Ice Cream Freezer / Margarine Crystallizer

Modular Scraped Surface Heat Exchanger Systems

Armfield miniature-scale technology is well established at offering developers the opportunity to run small trials, which provide enough information to enable scale-up to larger plant with confidence. The formulations go through similar physico-chemical changes as they would in production plant and real time data logging permits results to be recorded and repeated. The FT25 range of miniature-scale scraped surface heat exchangers has built-in control and flexibility with a graphic representation of the process on the touch screen control panel. The operator can choose the parameters wanted for any particular formulation. The FT25 has a number of configurations according to the required use.

Description

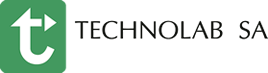

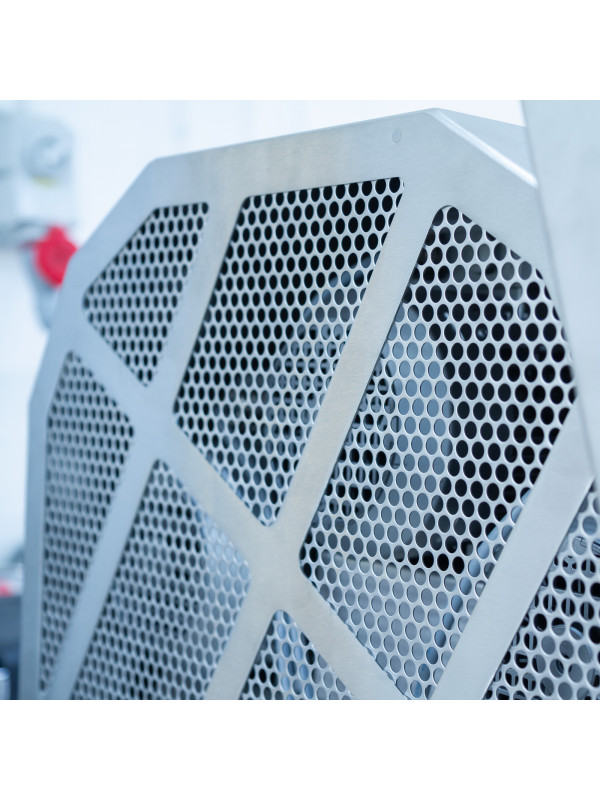

The FT25 Scraped Surface Heat Exchanger Series utilises the Armfield monocoque stainless steel cabinet with HIMI touch screen.

The working platform can accommodate one or two barrels (B) and a variable speed pinworker (P) alongside a progressive cavity feed pump (C). The unit housed in a Stainless Steel (304) uses a refrigeration system supplied within the cabinet and utilises a chilled, food grade refrigerant, which is pumped through the barrel jackets. An air incorporation system can also be added if required.

Small batch sizes enable rapid product testing.

Enhanced CIP facility available.

The FT25 has a number of configurations according to the use required.

Software

WINDOWS™ DATA CAPTURE SOFTWARE

A unique benefit of the Armfield miniature-scale food processing range is that the measured data may be captured and stored to disk. An Armfield FT25-DTA-ALITE Data Logging Accessory transfers results to a computer. Feed pump flow rate, barrel/pinworker speeds, temperatures and pressures can be monitored in realtime. The data can be displayed in graphical and tabular forms and printed. A computer with a USB port, and running Windows XP or later is required.

Typical Configurations

CONTINUOUS MARGARINE CRYSTALLISER

FT25BP-IF-C: One barrel and one pinworker

FT25BBP-IF-C: Two barrels and one pinworker. A resting tube for product settling and food grade refrigeration unit for process cooling are supplied. A range of oil emulsions can be processed.

CONTINUOUS ICE CREAM FREEZER

FT25BA-IF-C: One barrel. Air incorporation via a small air compressor and refrigeration. Overrun can be achieved up to 300% (dependant on product). Combined Ice Cream and Margarine System.

FT25BBPA-IF-C: Two barrels, one pinworker plus air incorporation.

Accessories

Data Logging Accessory: FT25-DTA-ALITE

Technical Specifications

HEAT EXCHANGER BARREL

Heat transfer area: 0.045m²

Shaft/barrel volume ratio: 1 : 3.5

Scraper blades: 4 along shaft stainless steel, 180° separation

Barrel length: 0.35m

Barrel working pressure: 20.0 bar

PINWORKER

No of pins on shaft: 20

No of pins on barrel: 42

BARREL/PINWORKER DRIVES

Variable speed ac motors, inverter controlled

Speed range: 0-1400rpm

REFRIGERATION SYSTEM

Food grade refrigerant: -25°C capability

FEED PUMPS

Progressive cavity pump

Process throughput: 0-20l/h, independent of back pressure

Particulate capability: up to 0.6mm

Fibre handling capability: up to 25mm

Air incorporation system: Air pump with multiple turn control valve and dial to vary overrun

NOTE: Air incorporation systems use a suction inlet and are not fitted with an inlet tank.

Requirements

Electricity supply: 220-240V 1ph 50Hz

Water supply: For refrigeration cooling Cooling water supply with flow rate of 3l/min @ 3bar and ≤20°C

Dimensions

Length: 1.01m

Width: 0.72m

Height: 1.45m