Sterile Vessel

- Availability: On Order

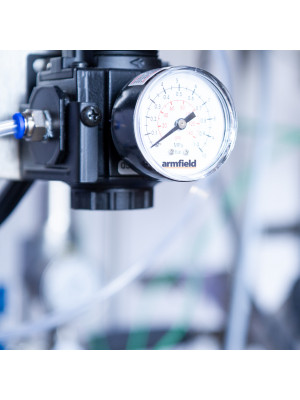

- Brand: Armfield

- Product Code: FT85

- Product viewed: 22836

Share:

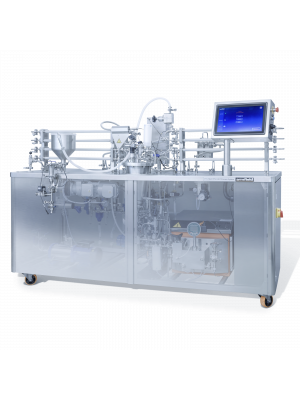

Sterile Vessel

Sterile Vessel

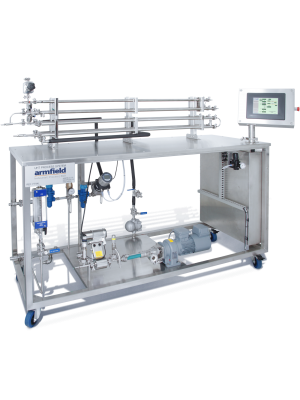

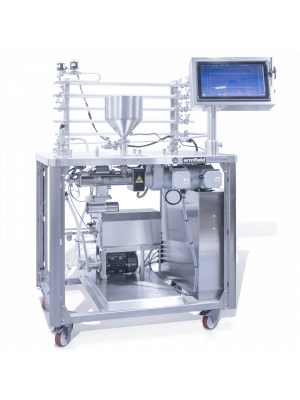

The Armfield FT85 Sterile Vessel can store UHT processed product for sterile filling at a later point. It eliminates product wastage associated with pilot-scale continuous operation filling systems that lack buffering capacity. The vessel is sited between Armfield’s UHT processing units and the FT83 Sterile Filling System and is available with vessel sizes from 10 to 30 litres (other sizes on request). It is designed for operation with Armfield systems, but can be operated with other equipment.

Features

- 10-30-litre vessel volume

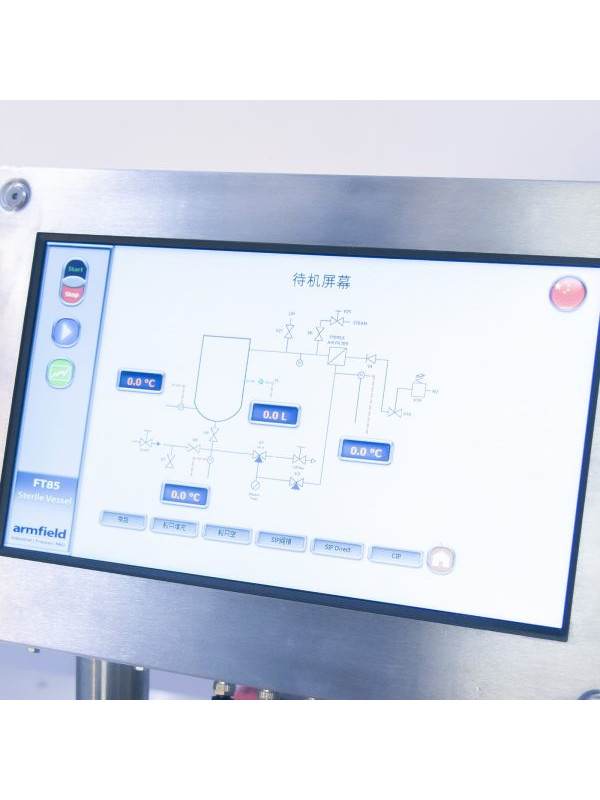

- Touchscreen display

- Variable sterilisation protocol control from touchscreen display

- Clean-in-place capability

- Can be integrated into Armfield or other UHT/filling systems

- Automated process operations

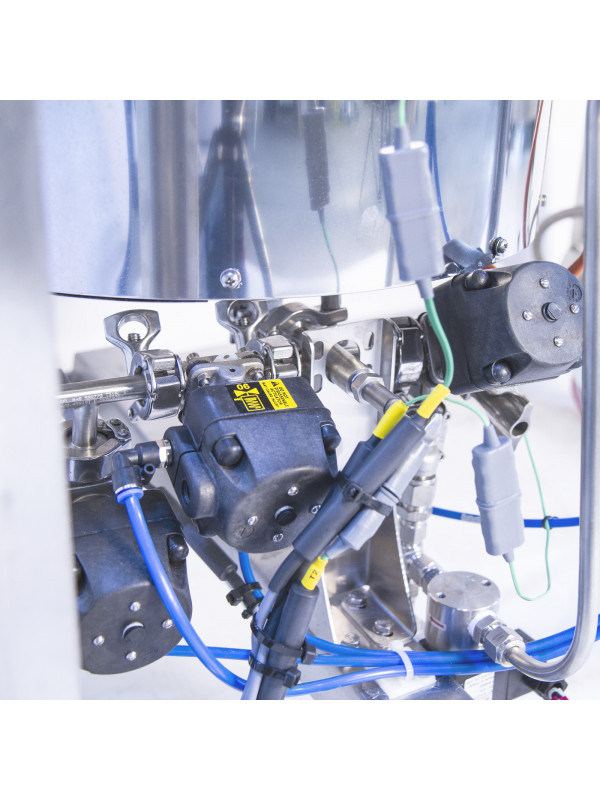

- Product agitation using a sterile gas supply

- Steam sterilisable by external or integral supply (FT85-10)

- Continuous level sensing

Benefits

- Sterile product can be stored until required

- No product wastage during filling

- Small footprint and mobile

- FT85 can be used for non-sterile processing

Description

The FT85 is controlled via a touchscreen mounted on the unit with modes for vessel filling, vessel emptying (bottling), sterilisation and cleaning. Vessel volumes range from 10 to 30 litres.

The UHT/filling system and the FT85 are first sterilised in separate processes. Time and temperature for the sterilisation process is set from the touchscreen. Once sterile, the UHT system is then placed in process mode and the FT85 into vessel fill mode. Sterilised product then fills the vessel.

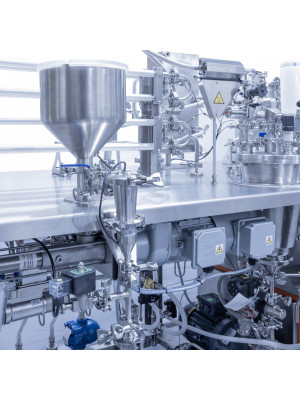

Once processing is complete flow bypasses the vessel and is then stopped. Sterile gas can be pumped into the vessel to provide product mixing. The vessel is then placed in Vessel Empty mode and positive head pressure on the vessel (sterile gas) is used to feed the product to the filler. The FT85 is cleaned in place using a spray ball with CIP pumping provided by the UHT system.

Steam Generator (FT85-10)

- FT85-10 enables sterilisation of the vessel without the need for an external steam supply.

Technical Specifications

| Vessel capacity: | 10-30 l (contact us for other sizes) |

| Max sterilisation temp: | 140°C |

Software

The armSOFT™ software displays the equipment flow diagram with readings displayed for all sensors. Time/ temperature sterilisation protocols are set or recalled from memory. There are also controls for feed pump stop/start and speed. A data tab offers several options for processing and displaying the data from the equipment in the form of graphs and results tables. Results are saved in a log, which can be viewed and manipulated with the armSOFT™ Results Viewer, or they can be exported to a generic spreadsheet format for further analysis.

Requirements

| Electrical supply: | Single-phase (see ordering codes) | |

| Air supply: | 6 bar with minimal air consumption | |

| Steam supply: | External steam supply required if FT85-10 option is not specified: | 4 bar @ 4 kg/hr |

| FT85-10: | This option requires a mains or softened water supply: | 1 bar @ 2 l/min |

Ordering codes

| FT85-A: | 220-240V | 1ph | 50Hz | 13A |

| FT85-G: | 220-240V | 1ph | 60Hz | 13A |

| FT85-10-A: | 220-240V | 1ph | 50Hz | 22A |

| FT85-10-G: | 220-240V | 1ph | 60Hz | 22A |

| FT85-10-C: | 380-415V | 3ph | 50Hz | 10A |

| FT85-10-D: | 208-220V | 3ph | 60Hz | 20A |

Overall dimensions

| Length: | 0.72m |

| Height: | 1.50m |

| Width: | 1.00m |

Shipping specification

| Volume: | 1.3m3 |

| Gross weight: | 200kg |