Générateur de Vapeur de Laboratoire

- Disponibilité: Sur commande

- Marque: Armfield

- Code produit: UOP10

- Produit vu: 18045

Partager:

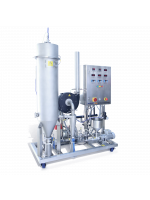

Générateur de Vapeur de Laboratoire

HEAT AND MASS TRANSFER UNIT OPERATIONS

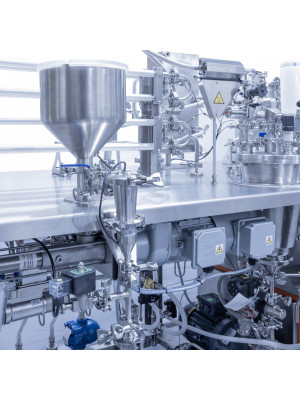

UOP10 Générateur de Vapeur de Laboratoire

Comme de nombreux laboratoires ne tiennent pas une source de vapeur centralisée ou fiable, Armfield UOP10 offre une chaudière avancée offrant un approvisionnement constant de la vapeur. L'unité compacte ne nécessite qu'une connexion à l'eau et de l' électricité pour le fonctionnement.

Ordering Specification

• A floor-standing continuous steam generator

• Splash proof electrical enclosure and switches

• Solid state level control on feed water tank

• Easy and safe access for maintenance and inspection, with door isolator to the main electrical enclosure

• Manufactured in accordance with Module G of the European Pressure Equipment directive 97/23/EC

• A comprehensive instruction manual

Description

The Armfield UOP10 Laboratory Steam Generator comprises a mains fed header tank with level control which supplies the pressure vessel via a quiet running, heavy duty, high pressure feed pump.

The pressure vessel is built to all relevant British and European standards. Being heavily insulated with two totally immersed Incoloy heating elements it provides a highly efficient and economical means of generating a continuous supply of steam.

The two heating elements are individually switched and the unit will operate satisfactorily on a single element.

The integral control panel houses an on/off mains switch with switchable test functions, LEDs display the operational status of the equipment.

The UOP10 is fully safeguarded via a Magnetic Circuit Breaker (MCB) and a Residual Current Device (RCD) to give a long trouble free life.

The components of the UOP10 are mounted within a steel cabinet finished with a high gloss stove enamel paint for corrosion resistance and long life. Front panels are hinged for easy access and are fitted with key operated handles.

It is recommended that for optimum life of the unit, feedwater should be demineralised.

Optional Accessory

In some countries it is illegal to blow down a steam boiler directly into the drainage system and a separator must be used. Armfield can offer a purpose built separator to fulfill this function. Users should check local regulations on the requirements for this unit.

UOP10-10: Blow Down Separator

Technical Details

Steam output at 100°C: 55kg/hr (continuous)

Heat output: 36kW

No. of heating elements: 2

Max. operating pressure: 10 bar

Requirements

Electrical Supply:

UOP10-C: 415V/3ph/50Hz

UOP10-D: 208V/3ph/60Hz

UOP10-E: 380V/3ph/50Hz

UOP10-F: 220v/3ph/60hz

Water Supply:

1.0l/min @ 2 bar maximum usage

Shipping Specification

Volume: 2.1m3

Gross weight: 490kg