Karbonator/Füller/Verschliesser

- Verfügbarkeit Auf Bestellung

- Hersteller Armfield

- Artikelnr. FT102XA

- Produkt angesehen: 13571

Teilen:

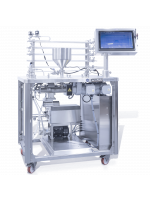

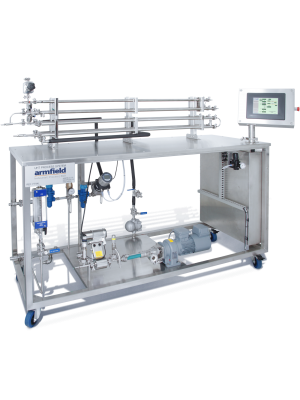

Karbonator/Füller/Verschliesser FT102XA

Der FT102XA ist die neueste hochpräzise Karbonisierungs- und Fülltechnologie. Sie können ein vorgemischtes Produkt oder Wasser und Sirup in einer Postmix-Konfiguration karbonisieren.

Abfüllen von alkoholfreien und alkoholischen Getränken in PET, Biokunststoff, Glas und Dosen mit Schraubverschluss, Kronenverschluss und jetzt einem integrierten Dosenverschließer.Dieser FT102XA hat viele neue Updates, darunter:

- Reduzierte Mindestchargenmengen

- Fähigkeit, stark schäumende Produkte zu karbonisieren

- Intern montierter Kühler zur Reduzierung des Platzbedarfs in Ihrem Labor

Weitere Aktualisierungen umfassen die Möglichkeit, eine doppelte Füll- und Verschließstation auf derselben Einheit zu haben, die den gelösten Sauerstoff und CO2 direkt misst.

Beschreibung

Der FT102XA ist die neueste hochpräzise Karbonisierungs- und Fülltechnologie. Sie können ein vorgemischtes Produkt oder Wasser und Sirup in einer Postmix-Konfiguration karbonisieren.

Abfüllen von alkoholfreien und alkoholischen Getränken in PET, Biokunststoff, Glas und Dosen mit Schraubverschluss, Kronenverschluss und jetzt einem integrierten Dosenverschließer.

Dieser FT102XA hat viele neue Updates, darunter:

- Reduzierte Mindestchargenmengen

- Fähigkeit, stark schäumende Produkte zu karbonisieren

- Intern montierter Kühler zur Reduzierung des Platzbedarfs in Ihrem Labor

Weitere Aktualisierungen umfassen die Möglichkeit, eine doppelte Füll- und Verschließstation auf derselben Einheit zu haben, die den gelösten Sauerstoff und CO2 direkt misst.

Technische Daten

Gasgehalt: 0-12g/l

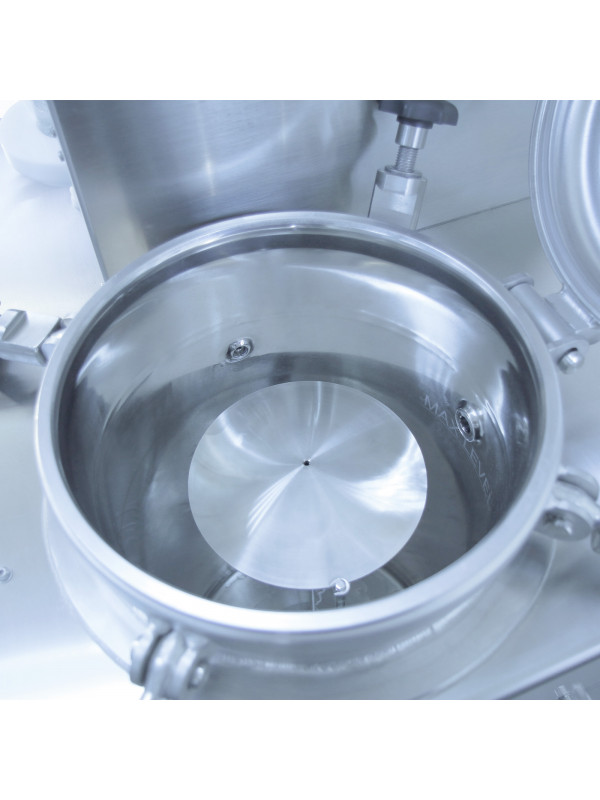

Schiffskapazität: 15 Liter oder 30 Liter Arbeitsvolumen

Kappungsmethoden: Schraube, Krone, Dosendeckel, ROPP, Rip-Cap

Gase: CO₂ , N₂ oder sichere, nicht brennbare Alternativen oder Mischungen

Kontaktflächen: Edelstahl 316L, Silikon in Lebensmittelqualität, PTFE, Borosilikatglas und andere lebensmittelechte Materialien

Betriebsmethoden: Chargenweise oder halbkontinuierlich

Mindestfüllmenge: 1 – 3 Liter (abhängig vom Behältervolumen)

Maximaler Behälterdruck: 4 bar

Funktionen & Vorteile

Eigenschaften:

- Genaue Kohlensäuregehalte von über 12 g/l (± 0,1 g/l)

- Befüllung von Dosen, PET- und Glasflaschen

- Schraube, Krone, Rip-Cap und ROPP-Verschluss

- Dosenverschluss

- CO2 Recycling zur umweltfreundlichen Verarbeitung

- Entlüftung

- Behälterspülung

- Neues Vakuumsystem kompatibel mit stark schäumenden Produkten

- Flaschendruckmessung

- Vor- und Nachmischfunktion

- Sirupdosierung in die Flasche

- ArmBUS-Steuerungssystem mit 32 Prozessrezepten und Flexibilität der Computersteuerung gegenüber der SPS-Steuerung

- Vollständige Datenerfassung durch ArmBUS Data Viewer (nach Excel exportierbar)

- Option mit zwei Füllköpfen erhältlich

Vorteile:

- Reduzierte Bewegung der Flasche erhöht die Genauigkeit und Zuverlässigkeit der Karbonisierung

- Integrierter hocheffizienter Kühler reduziert den Platzbedarf im Labor

- Abnehmbare Seitenwände und IP65-Schaltschrank für einfachen Zugang zu internen Komponenten und Abspritzen bei Bedarf

- Kann als eigenständige Einheit oder mit dem Gefäß für kontinuierliche Zufuhr FT102XA-44 betrieben werden

- Kein externer Kühler oder Eiswasserversorgung erforderlich

- Schraubverschlusskopf

- Kronenkappenkopf

- Verschließkopf für Dosen

- Halsstütze für PET-Flaschen

- Zusätzliche Zentrierringe

- Sirupdosierung

- Heißfüllung

- Dauerbetriebsfähigkeit

- Entlüftung

- Atline-Sauerstoffsensor

- At-Line-CO2-Messung

- Strom: – FT102XA-A: 230 V 50 Hz 25 A (eine Steckdose erforderlich)

– FT102XA-G: 230 V 60 Hz 16 A und 110 V 60 Hz 8 A - CO2 Versorgung mit manuellem Regler, 6 bar

- Stickstoffversorgung mit Handregler, 6 bar (falls verwendet)

- Druckluftversorgung mit Handregler, 6 bar

- Wasser für Kühler bei Inbetriebnahme

- Entwässerung

- FT102XA-15-A

- FT102XA-30-A

Zubehör

Verknüpfte Produkte

FT140X: Vorgeschalteter Mischbehälter

FT74XA: HTST- und UHT-System

FT174X: HTST- und UHT-System

FT110X: Benchtop-Lösungsmittelextraktionssystem

FT111X: Lösungsmittelextraktionssystem

Anforderungen

Versandspezifikationen für Verpackungen und Kisten

Verpackte Versandspezifikationen

Volumen: 3,2 m3

Nettogewicht: 410kg

Bruttogewicht: 500 kg

Abmessungen

Länge: 1,2 m

Breite: 0,80 m

Höhe: 1,75 m